Top Tips for Efficient Commercial Refrigeration Repair in Toronto

Top Tips for Efficient Commercial Refrigeration Repair in Toronto

Blog Article

Fixing Industrial Refrigeration Fixing: Methods for Quick and Effective Fixes

In the realm of industrial refrigeration, the requirement for swift and exact troubleshooting methods is paramount. When a refrigeration system malfunctions, the repercussions can be pricey and turbulent to service procedures. Recognizing the usual concerns that pester industrial refrigeration systems and having a toolkit of analysis techniques available can make all the difference in swiftly identifying and fixing problems. As we browse with the complexities of troubleshooting commercial refrigeration fixing, we will uncover the key strategies for solving issues efficiently, guaranteeing that companies can maintain ideal cooling efficiency and minimize downtime.

Usual Industrial Refrigeration Issues

Commercial refrigeration systems generally come across a series of functional concerns that can interrupt their efficiency and efficiency. One prevalent concern is inappropriate temperature control, which can bring about food perishing and waste otherwise quickly dealt with. This issue may come from issues with the thermostat, evaporator fan, or condenser coils, requiring comprehensive examination to identify the origin. An additional usual issue is inadequate air movement, frequently brought on by blockages in the vents or a malfunctioning fan. Poor airflow can result in temperature disparities within the refrigerator or freezer, impacting the top quality and security of saved products.

Moreover, cooling agent leaks present a considerable issue as they not only affect the cooling ability of the system yet also add to ecological harm. Regular cleaning and maintenance can assist avoid this issue and prolong the lifespan of the refrigeration system.

Diagnostic Devices and Methods

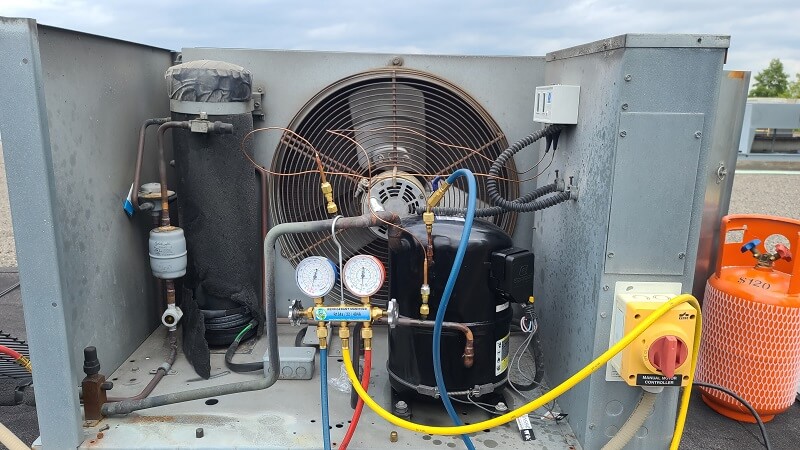

Efficient troubleshooting of business refrigeration systems counts heavily on making use of specialized diagnostic tools and strategies to recognize and deal with underlying problems effectively. One vital analysis device is the multimeter, which assists technicians determine voltage, current, and resistance in various parts such as compressors, electric motors, and thaw heaters. Thermostats are additionally vital for evaluating temperature differentials throughout the system to determine possible issues like refrigerant leaks or improper air flow. Additionally, leakage detection devices like electronic leakage detectors or ultraviolet dye packages are vital for finding cooling agent leakages that can result in system inadequacies.

Data loggers can be utilized to monitor system performance over time and detect fads that may show recurring problems. By combining these analysis tools and methods, service technicians can effectively repair business refrigeration systems and offer fast and exact fixings, lessening downtime and ensuring ideal system efficiency.

Quick Fixes for Refrigeration Troubles

When encountered with refrigeration problems, service technicians can carry out quick fixes to attend to usual concerns swiftly and successfully. If the refrigeration device is not cooling down effectively, checking and adjusting the thermostat settings may supply a quick solution before even more in-depth troubleshooting is required. By carrying out these quick repairs, service technicians can deal with usual refrigeration issues successfully and keep industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Executing an aggressive upkeep routine is essential for guaranteeing the durability and optimum efficiency of commercial refrigeration systems. Routine upkeep not just aids stop pricey malfunctions yet also makes certain that the equipment operates effectively, saving energy and reducing total operating expense. Below are some preventative upkeep pointers to keep business refrigeration systems running efficiently:

Examine and Replace Filters: Filthy filters can restrict air flow, making the system work more challenging and possibly triggering damages. Examine and change filters consistently to avoid problems.

Inspect Seals and Gaskets: Leaking seals and gaskets can result in temperature variations and energy wastefulness. Changing and examining damaged seals can assist maintain constant temperature levels.

Specialist Assistance and Provider

To keep the ideal performance attained with regular preventative maintenance, looking for specialist assistance and services for industrial refrigeration systems is crucial. Professional specialists possess the experience and specialized knowledge required to diagnose and address intricate issues efficiently. When encountering tough refrigeration issues, relying upon specialist support can conserve both money and time in the future.

Specialist services provide advantages such as access to sophisticated devices and equipment, ensuring that repair services are accomplished successfully. In addition, professionals are trained to adhere to market regulations and safety and security requirements, decreasing the risk of crashes and making sure conformity with legal demands.

Final Thought

In verdict, troubleshooting commercial refrigeration repair service needs an organized approach to identifying common problems, using analysis devices and techniques, carrying out quick repairs, and prioritizing preventative maintenance. Professional assistance and solutions might be necessary for even more complex problems - commercial refrigeration repair. By following these approaches, companies can guarantee their refrigeration systems operate effectively and properly, minimizing downtime and possible losses

Understanding the usual issues that pester commercial refrigeration systems and having a toolkit of analysis techniques at your disposal can make all the difference in swiftly recognizing and treating problems.Efficient troubleshooting of commercial refrigeration systems counts greatly on utilizing specialized diagnostic tools and strategies to recognize and solve underlying problems successfully. By integrating these diagnostic devices and techniques, service technicians can effectively repair commercial refrigeration systems and provide exact and fast repair services, decreasing downtime and making sure optimal system efficiency.

By carrying out these fast solutions, technicians can attend to common refrigeration problems effectively and keep industrial refrigeration systems running smoothly.

Additionally, specialist support can assist extend look here the life expectancy of commercial refrigeration systems by recognizing possible problems before they intensify.

Report this page